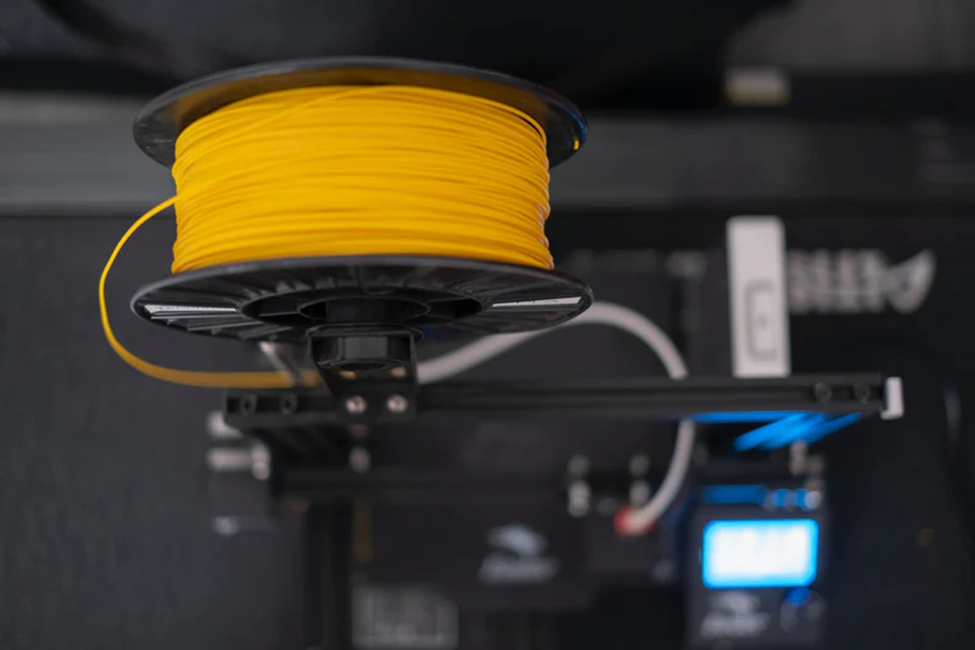

Now that you have some TPU filament in your possession, you can start printing with it.

Fantastic! With flexible filaments, 3D printing has access to a completely new realm of possibilities. However, printing with TPU can be more challenging than with standard filaments like PLA or ABS. Don't worry; with the correct settings and a few pointers, you can print flexible items quickly. Thermoplastic polyurethane, or TPU, is a flexible plastic that takes on shape when cooled and becomes pliable when heated. You can print items that stretch, compress, and bend because it possesses qualities similar to both plastic and rubber. The secret to TPU is to move slowly. You'll have to change the temperature, retraction parameters, print speed, and other things. Utilize these pointers and you’ll master printing with flexible TPU filament.

What is TPU Filament?

TPU, or thermoplastic polyurethane, is a flexible filament used for 3D printing. TPU is very elastic and resistant to impact, allowing it to flex and bend without breaking. Because of this, printing on flexible objects like watchbands, phone covers, and shoe bottoms is a breeze.

TPU is available in a range of shore hardnesses, from extremely soft (almost rubber-like) to quite stiff. TPU will be more flexible the softer it is. TPU can be printed using a lot of 3D printers, but you'll need an all-metal hotend that can melt TPU at a high enough temperature (usually 220-260 °C) and a direct drive extruder.

It is necessary to make some tweaks to your settings while printing with TPU. Printing at a slower pace—roughly 15 to 30 mm/s—will allow the TPU to stretch and adhere to the preceding layer. Additionally, you want to raise the layer height to at least 0.2 mm. This improves the TPU's ability to bind together. The first layer adhesion can be aided by applying an adhesive, such as glue sticks or hairspray, to the print bed.

When you get the settings just right, printing with TPU can be incredibly satisfying. You can make prints with this flexible filament that are simply not achievable with stiff materials. Although learning it takes some time, TPU opens up a whole new world of possibilities and applications for 3D printing. You can quickly print flexible parts of excellent quality by using the appropriate methods and modifications!

TPU Printing Settings and Tips

You will need to adjust your standard settings in order to print with flexible TPU filament. Because TPU is more flexible than ordinary filament, it needs to be printed at a higher temperature and at a slower speed.

Printing Temperature

Usually, TPU prints at higher temperatures—between 220-235°C. As necessary, start at 225°C and adjust. TPU won't adhere well at lower temperatures and clog your nozzle. Locate the sweet spot for your particular filament because it can burn at higher temperatures.

Slow Down Your Print Speed

Because TPU is flexible, it requires some time to adhere to the prior layer. For optimal results, print at 15–25 mm/s. Any quicker and you run the risk of poor layer adhesion or clogging.

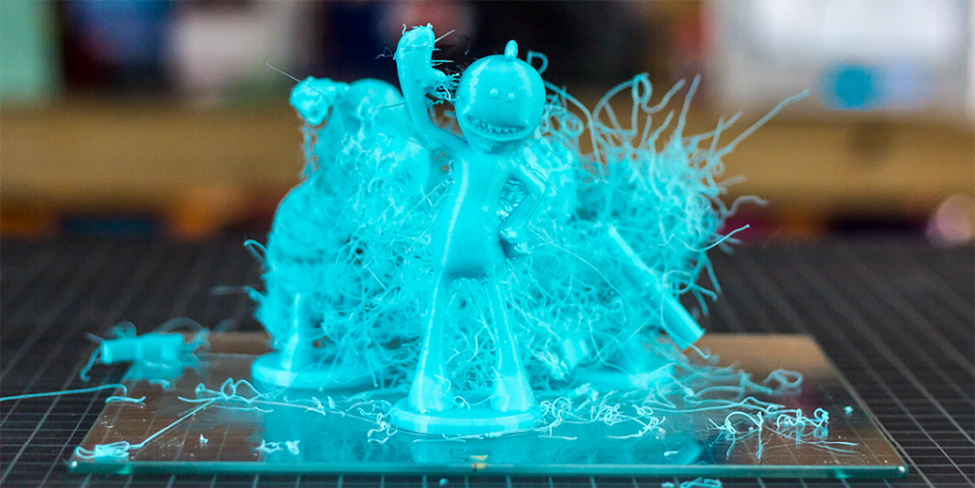

Increase Retraction

Retraction prevents oozing and stringing by drawing the filament back. When printing TPU, increase the retraction distance to 6-8 mm and the speed to 25-30 mm/s. This contributes to a clear print.

Use Direct Drive Extruder

Since TPU is pliable and soft, a direct drive extruder is the ideal tool for using it. Better control and a decreased risk of filament bending or buckling are provided by direct drive extruders, which press the filament straight into the hotend. Printing TPU might still be possible with a Bowden tube setup, albeit at a slower rate.

Increase Layer Height

TPU prints perform better when a higher layer height of 0.2-0.25 mm is used. Taller layers allow the filament to cool more slowly, improving its ability to hold its shape. Shorter layers may result in an unsuccessful print.

You can quickly become proficient at producing TPU prints if you have the proper equipment, temps, speeds, and settings. Be patient, go slow, and do some test prints; the outcome will be worthwhile! A whole new range of imaginative and useful 3Dprinting possibilities are made possible by flexible filaments.

How to Choose Right TPU Filament

A few things to think about when selecting a TPU filament for your 3D printing project are as follows:

Hardness

TPU filaments are available in a variety of hardness levels, ranging from extremely soft—almost like rubber bands—to fairly stiff—yet still flexible. U3D and other softer filaments work well for grips, phone cases, and mechanical components. Consider how much durability and flex your application will require.

Printability

It can be more difficult to print with more flexible TPUs; slower speeds and a higher temperature are needed to prevent clogs. Consider starting with a medium hardness, such as U3D, if you're new to printing with TPU. It prints well on the majority of desktop printers. With more practice, you can experiment with stiffer or softer filaments.

Layer Adhesion

Since the layers can fuse together more readily, softer TPU filaments typically offer better interlayer adhesion. A smoother, more watertight print is the outcome of this. More brittle TPUs are more likely to delaminate and exhibit obvious layer lines. To achieve better layer bonding with stiffer TPUs, increase the flow rate, print temperature, and number of perimeters.

Color

Neon shades are among the vivid colors that TPU filaments come in. Certain brands provide multi-color packs that make it simple to switch out the filament mid-print to create intricate color patterns or rainbow effects. Basic colors like black, white, and gray work well for mechanical parts.

You can select a TPU filament that is best suited for your specific 3D printing project by taking into account factors like color options, printability, hardness, and layer adhesion. To get the best results, don't be afraid to experiment a little and adjust the printer's settings. High-quality parts can be printed quickly with the correct filament and technique!

TPU Print Adhesion Troubleshooting

TPU (thermoplastic polyuthane) filament printing can be difficult at first. Here are some guidelines to help you improve TPU print adhesion and accomplish successful prints.

Printing Surface

Ensure that the print bed surface you're using is smooth, such as a polypropylene sheet, glass, or PEI. During printing, rough surfaces, such as painter's tape, can snag the TPU and cause layer separation. You can use bed adhesive, hairspray, or a glue stick to give the print surface more adherence.

Slow Down

The optimal print speed for TPU is 15–30 mm/s. The TPU has more time to adhere to the preceding layer at slower speeds. Faster speeds may result in stringiness and poor adhesion. Additionally, keep in mind that making sudden direction changes in your print may cause the TPU to lift off the bed.

Increase Nozzle Temperature

TPU normally prints at 220-230°C, which is a higher temperature. The TPU melts and fuses together more effectively at the higher heat. Verify that the part cooling fan is either fully off or set to a low setting. Overcooling the TPU can hinder the proper adhesion of layers.

Avoid Over Extrusion

When printing TPU, use an extrusion multiplier of 0.8–0.9. Poor layer bonding and excessive buildup are caused by over-extrusion of TPU. For optimal filament extrusion, adjust the extruder steps and flow rate specifically for TPU.

Consider an Enclosure

By preserving a constant temperature surrounding the print, printing TPU in an enclosure promotes adhesion and reduces warping. Try covering your printer with a big cardboard box that has some holes cut out if you don't have an enclosure. The enclosure only serves to stabilize outside temperatures; it is not necessary to heat it.

You will soon be printing robust, flexible TPU parts with a little experimentation with these settings. Please contact me with any more inquiries!

Cool TPU Print Projects and Ideas

Now that you understand the fundamentals of printing with TPU, it's time to try out some enjoyable projects. Because of TPU's flexibility and durability, there are many opportunities for innovative and practical prints.

Phone Cases

TPU makes the best personalized phone cases. To print a basic case, you can use free 3D models from websites like Thingiverse or create your own with 3D design software. TPU covers are flexible and impact resistant, fitting your phone securely.

Drone Parts

TPU is excellent for printing replacement parts for drones and quadcopters, such as landing gear, camera mounts, and propeller guards. The material has enough give to absorb shocks while still holding up well to outdoor conditions.

Robotics Parts

TPU can be used for joints, tires, tank treads, and wheels in robotics projects. These components grip and glide more easily thanks to its elasticity. TPU is suitable for outdoor robotics because it is waterproof as well.

Cosplay Accessories

Flexible filaments provide new opportunities for cosplayers and costumers. Masks, armor, props, and other accessories that require bending and flexing can be printed. To give the TPU a polished, smooth surface, sand and paint it.

Shoes

Yes, you can use TPU to make shoes with 30 prints! Parts of the shoe, such as the heel or sole, can be made entirely of the material. A set of 30 printed TPU shoes and insoles can offer personalized fit and support. In addition, they're a fantastic choice if your foot shape or shoe size are unusual.

With TPU, the possibilities are endless. Numerous flexible and durable prints for daily use, hobbies, cosplay, and other purposes are made possible by this amazing material. Play around and see what you can come up with! With this entertaining and useful filament, you can let your creativity run wild.

Conclusion

That is all the information you require to begin printing with TPU filament. TPU creates an entirely new realm of possibilities for flexible and long-lasting 30 prints, even though it might necessitate some modifications to your typical printing procedure. The most important things to remember are to enable retraction, reduce print speed, and raise the nozzle temperature. You can quickly print flexible phone cases, watch bands, and other items if you adhere to these tips. TPU filament opens up new creative possibilities for you. Try it out and discover your inner master of flexible filament! First thing you print, will be?

Leave a Reply