Hello there, tech nerd! Ever wonder what kinds of technologies are available and how 3D printers actually operate? Most likely, you've heard that 3D printing is transforming manufacturing and opening up a ton of new uses, but how does it all work exactly? There are several distinct kinds of 3D printing, and each has advantages and good applications. Read on to obtain an overview of the main 3D printing kinds so you can find what suits your needs, whether you're wanting to start 3D printing as a hobby or want to better grasp the technologies enabling significant advancements. A lot of cutting-edge technology is used by 3D printers, including melting plastic, using lasers, and even producing living cells.

Overview of 3D Printing and How It Works

Making three dimensional solid products from a digital file is a process known as 3D printing, sometimes known as additive manufacturing. A 3D printer builds up layers of material to make an object until it is completely formed. Each of these layers might be thought of as a horizontal cross-section of the final object that has been finely cut.

Fused Deposition Modeling

3D printing, also known as additive manufacturing, is a technique for creating physical, three-dimensional objects from digital files. A 3D printer creates an object by layering material until it is fully formed. You may see each of these layers as a precisely sliced horizontal cross-section of the final item.

Stereolithography

Liquid resin is cured and hardened into layers during SLA using an ultraviolet (UV) laser. It creates items with a smooth surface finish and great resolution. Photopolymers are the only available materials, but new resins offer more choices. SLA printers typically cost more money.

Selective Laser Sintering

A solid mass is created by SLS by fusing tiny metal, ceramic, glass, or polymer powder particles together using a laser. It allows for the printing of intricate, multi-material pieces. Nylon, glass, metal alloys, and more materials are available. SLS printers are often expensive to buy and maintain.

Jetting of Materials

Droplets of construction material are sprayed onto the build platform using material jetting to create layers. Wax and photopolymers are employed. It has high resolution color and multi-material printing capabilities. The cost of material jetting printers is high. In conclusion, 3D printing has completely changed how products are designed and made. Both experts and enthusiasts can find solutions in the variety of technology and materials available. Rapid prototyping and customization are now more accessible thanks to 3D printing, spurring creativity all across the world.

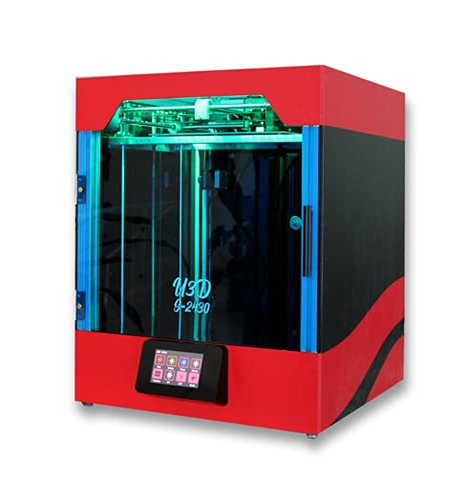

Fused Deposition Modeling (FDM) - The Most Common 3D Printing Method

The most popular 3D printing technique is called Fused Deposition Modeling, or FDM. It creates an item by heating and extruding thermoplastic filament, which hardens into layers.

Materials

Acrylonitrile Butadiene Styrene (ABS) and Polylactic Acid (PLA) filaments, which are non-toxic and biodegradable plastics, are used in FDM printers. Although ABS is more durable, PLA is more common because it makes printing easier.

How It Works

- The FDM printer software loads the 3D design and cuts it into layers.

- After heating up, the printer extrudes the filament onto the build plate using its nozzle.

- As the nozzle passes over the build plate, layers are added by depositing melted filament that later hardens.

- The build plate descends after each completed layer, and the subsequent layer is printed on top. Up till the object is finished, this is repeated.

FDM is economical, easy to use, and the materials are cheap. Parts may be durable and sturdy. Layer lines are frequently evident and prints can be scratchy. Limited resolution and detail. Parts could warp or need support systems. A simple, user-friendly technique to start with is FDM 3D printing. FDM is most appropriate for larger prints when great detail is not a concern, even if resolution and quality are continually improving. FDM prints may still be extremely impressive and helpful with some post-processing!

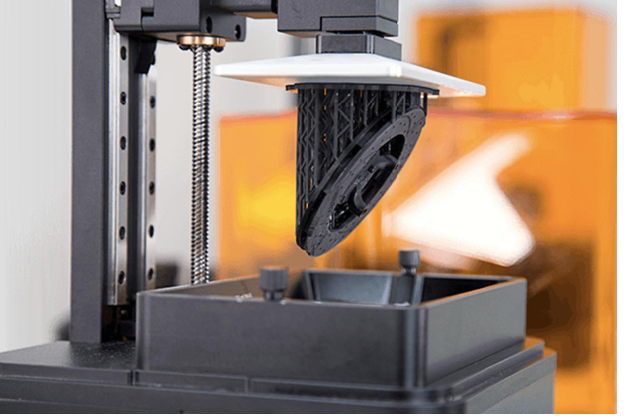

Stereolithography (SLA) - High Resolution 3D Printing

4One of the most accurate 3D printing techniques is stereolithography, or SLA. Liquid photopolymer resin is cured and hardened into solid plastic layers using an ultraviolet (UV) laser. The cross-section of the 3D model is traced by the laser beam onto the resin's surface, hardening it and fusing it to the layer below. The next layer is then created as the build platform is lowered into the resin tank by a modest amount, typically 0.05 mm to 0.15 mm. Until the entire 3D print is finished, this is repeated.

SLA is the best option for pieces that need to be highly precise and defined since it produces 3D prints with smooth surface details and precise tolerances. The flawless finish produced by the layer resolution, which can be as high as 0.025 mm, requires little to no post-processing. Additionally, SLA materials are temperature-resistant, with certain resins able to tolerate temperatures of above 300 °C.

SLA is the best option for pieces that need to be highly precise and defined since it produces 3D prints with smooth surface details and precise tolerances. The flawless finish produced by the layer resolution, which can be as high as 0.025 mm, requires little to no post-processing. Additionally, SLA materials are temperature-resistant, with certain resins able to tolerate temperatures of above 300 °C.

If you require a high resolution, dimensionally correct 3D print with smooth features, SLA is a fantastic option. Compared to competing technologies like CNC machining, SLA can achieve precise tolerances and a superior quality at lower prices for low volume production. SLA is widely used in industry to quickly prototype items with complex geometry. FDM or SLS may be preferable options if high throughput or cheap costs are important considerations. However, SLA 3D printing thrives when accuracy and quality are of the utmost importance.

Selective Laser Sintering (SLS) - Durable Functional Prototyping

A laser is used in the additive manufacturing technique known as selective laser sintering (SLS) to fuse powdered materials into three-dimensional forms. It makes it possible to produce robust, functional prototypes with intricate geometries directly from 3D CAD data.

With SLS, layers of powdered material—typically nylon or polyamide—are fused together selectively to form solid 3D shapes. First, the build platform is covered with a layer of powder. The powder particles are then fused together as the laser follows the pattern of the first layer. Another layer of powder is poured over the first layer as the platform descends. The second layer is subsequently fused to the first by the laser. Up till the portion is finished, this process is repeated.

Since the raw material for SLS is a powder rather than a liquid, it may create objects that are extremely robust compared to stereolithography (SLA), which employs liquid polymer resins. There is no need for support structures because the powder surrounds and supports the part during construction. Thin walls and intricate geometries are achievable in parts that are not conceivable with conventional 3D printing processes.

These are the primary advantages of SLS 3D printing:

- Extremely robust and useful prototypes. Heat, chemicals, and mechanical stress can all be tolerated by SLS parts.

- Geometries that are complex. Complex forms and thin features are supported by powder.

- Rapid revisions. New parts may be quickly produced, and design changes are simple to implement.

- Surface finish is smooth. SLS creates a surface that is smooth and waxy and requires little post-processing.

The drawbacks include the higher cost of SLS printers and supplies. The surplus powder also needs to be handled and stored in a specific way. However, SLS can be a cost-effective option for developing robust prototypes and tooling for low-volume manufacturing.

SLS 3D printing is a fantastic choice to take into account for your next project if you require strong prototypes that can perform like end-use parts. It is a flexible and useful technology for product development since it can print very complicated shapes and is compatible with a wide range of engineering-grade materials.

Binder Jetting - Full Color 3D Printing

One of the most adaptable full-color 3D printing techniques is binder jetting. Binder jetting, as opposed to other techniques, uses a liquid bonding agent, or binder, to link powder components together layer by layer in order to print overhangs and bridges.

How it Works

- The build platform is covered with a thin coating of a powdery material, such as sand.

- Droplets of a liquid binding agent are selectively deposited onto the powder bed by an inkjet print head as it passes over the powder.

- Until the section is finished, another layer of powder is applied on top, and the process is repeated.

- The part is taken out of the surplus powder after printing, then it is baked to cure it..

Binder jetting has the ability to rapidly print intricately detailed complicated structures. It enables you to print parts directly in the 3D printer in full CMYK color with a flawless finish. There are many different materials available, including sandstone, ceramics, metals, and sugar. To increase part strength and finish, post-processing is frequently necessary. The following are some of the main advantages of binder jetting: Full color 3D printing - Use CMYK inkjet print heads to provide vivid color.

- High output - Print numerous components simultaneously at quick print rates.

- Fine features and intricate details - Create parts with high resolution.

- Complex geometries - Internal channels, overhangs, and lattice structures are simple to print.

- A variety of powder materials, including sand, metal, ceramics, and sugar, are available.

- Little waste: Unbound powder supports the printed part and is recycled.

Binder jetting is a fantastic choice if you're looking for a cheap full-color 3D printing method. It enables you to print high volumes of visually appealing prototypes, models, works of art, or finished products at a comparatively low price. You may create items that precisely fit your demands thanks to the variety of powder materials that are accessible and the post-processing methods.

Conclusion

The fundamentals of the main categories of 3D printing technology available today are covered by that. As you can see, 3D printing has advanced considerably since its inception and is still advancing quickly. There is a 3D printing alternative for you whether you want to start a business, take up a new pastime, or just want to see what all the excitement is about. There are countless opportunities for creation. Who knows, maybe you'll create something that alters the course of history. Just start printing for the time being, and see where your creativity takes you! Get out there and start writing the future because it is yet to be.

Leave a Reply