You are aware that certain filaments for 3D printing can be delicate and break easily? Fortunately, PA carbon fiber filament can save the day. Parts that are truly long-lasting can be made with this robust and resilient filament. We'll look at the finest applications for this high-performance substance in this post. PA carbon fiber expands the capabilities of your 3D printer, enabling you to create anything from hobby projects to working prototypes. We'll examine the best print parameters, examine the operation of the carbon fiber reinforcement, and showcase some of the most inventive applications we've come across. You can print taller components with less chance of breaking, decrease warping, and enhance bed adhesion with these recommendations, regardless of whether you're new to using this filament or want to get more out of it. Let's dive in and unleash the full potential of PA carbon fiber!

An Introduction to PA Carbon Fiber Filament

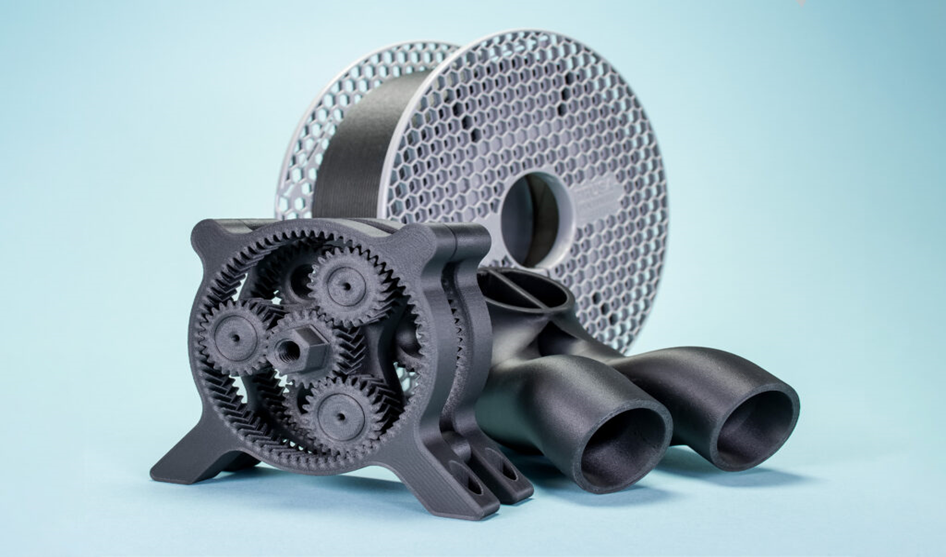

For 3D printing, PA carbon fiber filament is a robust, lightweight material. Its exceptional strength-to-weight ratio is a result of the carbon fiber strands that are incorporated into the nylon polymers. For printing objects that must withstand impact or stress, this filament is perfect. Among the greatest applications for PA carbon fiber filament are:

- Drone parts and frames. This filament's endurance and small weight make it ideal for aerial aircraft. With PA carbon fiber filament, printed drone frames can have a high strength-to-weight ratio.

- The robotic components. This filament works great for printing joints, gears, limbs, and other parts that need to be precise and stiff while designing and constructing robots.

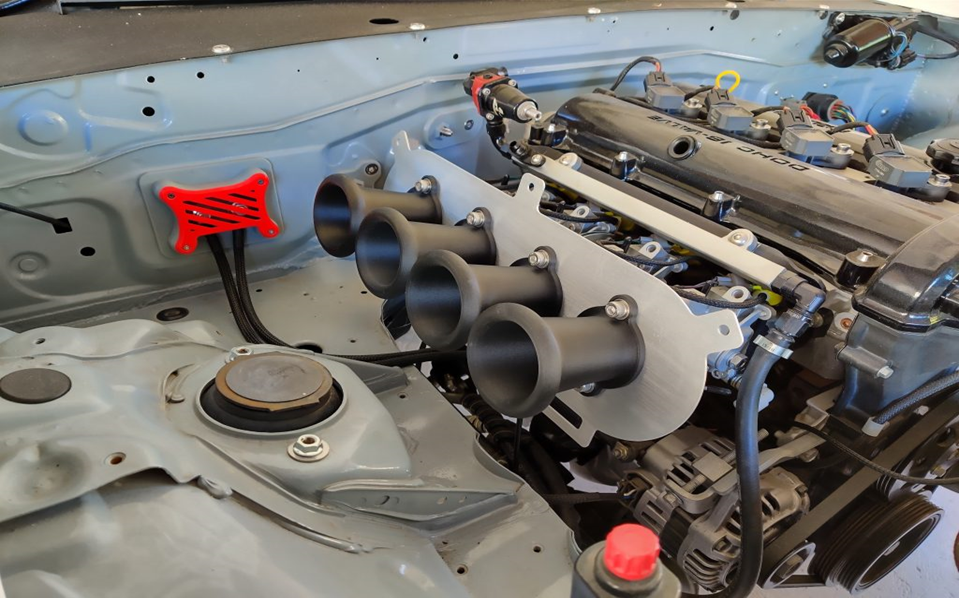

- Auto components. It is possible to print strong, lightweight car components like grills, dashboards, mirrors, and air vents with PA carbon fiber filament.

- Athletic gear. For printing products like kayak paddles, running shoes, cycling helmets, and other equipment where light weight and excellent performance are crucial, this filament is perfect.

- Handles for tools. The PA carbon fiber filament's toughness and stiffness make it appropriate for printing tools like wrenches and screwdrivers, pliers, and other tool handles.

There are certain handling and care requirements for PA carbon fiber filament. Because the filament can be abrasive, you'll need a printer with an all-metal 0.239m1 and a hardened steel nozzle. Additionally, higher print temperatures of 260–280°C are required. This cutting-edge filament can create extraordinarily sturdy, lightweight 3D printed parts with the correct tools and settings.

Key Properties and Benefits of PA Carbon Fiber Filament

Polyamide carbon fiber filament, or PA carbon fiber filament, has several beneficial qualities that make it excellent for a variety of uses. The following are the main advantages of using this material.

High strength-to-weight ratio

PA carbon fiber filament is a remarkably light-weight and robust material. It can sustain large stresses and impacts without adding a lot of weight because of its high strength-to-weight ratio. This makes it perfect for uses where weight reduction is crucial, such as in the sporting goods, aircraft, and automobile industries.

Dimensional stability

Because of its minimal thermal expansion, this filament material maintains its shape effectively. In hot weather, it does not readily distort or deform. PA carbon fiber products can be used in high-heat applications where precise dimensions and tolerances are needed thanks to a trait known as dimensional stability.

Chemical resistance

The PA carbon fiber filament is not easily harmed by solvents, oils, or chemicals. When it comes into contact with a lot of severe substances, it does not degrade or weaken. The material is appropriate for parts that come into touch with chemicals, as those used in chemical plants, refineries, and laboratories, because of its chemical resistance.

High stiffness

The special qualities of PA carbon fiber filament allow for innovation in a variety of industries. You can decide if this high-performance material is the best option for your upcoming design or product by being aware of its main advantages. Due of its exceptional strength, low weight, dimensional stability, chemical resistance, and stiffness, this filament can be utilized in extremely demanding applications where its performance would be inferior to that of other materials.

Best Uses for PA Carbon Fiber Filament

There are numerous practical uses for PA carbon fiber filament, sometimes referred to as nylon filament infused with carbon fiber, in 3D printing. Parts made of this material are robust and lightweight at the same time.

Drones and RC Parts

The propellers, limbs, and chassis of RC vehicles and drones may be printed with ease thanks to the strength and lightweight nature of PA carbon fiber filament. These components can survive small collisions without breaking because of the material's impact resistance. Very stiff items can be produced with PA carbon fiber filament, but to avoid warping, you might need to utilize a heated print bed.

Tool Handles and Clips

For printing tool handles, clamps, clips, and brackets, this filament is excellent. Parts made using PA carbon fiber filament are lightweight and capable of holding objects firmly. Because of the material's strong fatigue resistance, parts will endure frequent use.

Robotics Parts

PA carbon fiber filament is helpful for printing joints, linkages, and wheel hubs if you create robots or other mechanical devices. Good strength and rigidity are provided by the carbon fiber reinforcing, which are crucial characteristics for moving parts. Additionally, lightweight robot chassis and frames may be produced using this filament.

Athletic Equipment

PA carbon fiber filament can make sense for sports equipment such as archery bows, lacrosse clubs, and bicycle helmets. It has the potential to print lightweight, impact-resistant parts that are reliable, safe, and effective. Particularly for bike helmets, materials need to be strong, stiff, and impact-resistant.

Strong, stiff, and lightweight products are produced with PA carbon fiber filament, which is ideal for applications needing these characteristics. You can get a smooth finish and good layer adhesion with the correct 3D printer settings. You should try printing with PA carbon fiber filament if you're interested in creating lightweight but durable products.

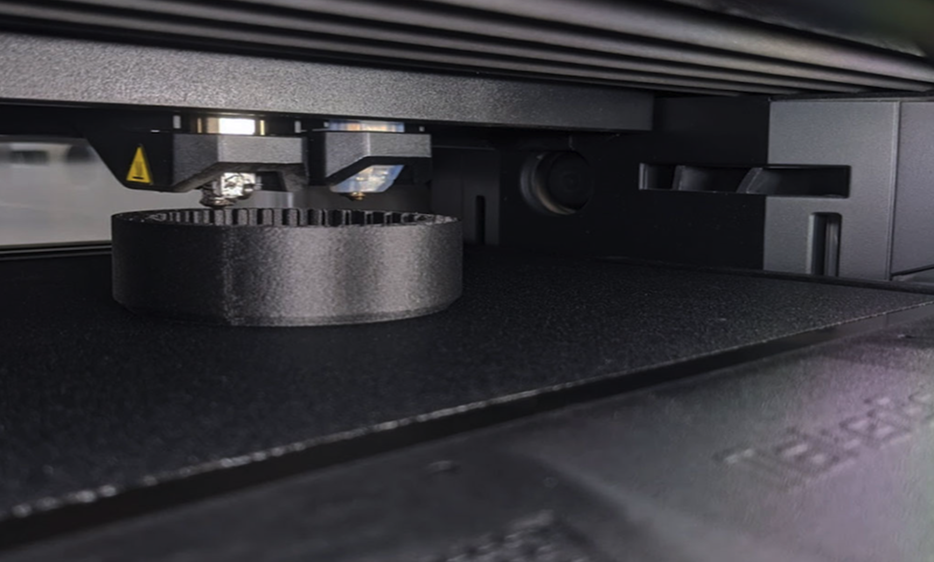

How to Print Successfully With PA Carbon Fiber Filament

There are a few pointers to remember in order to get the most out of PA carbon fiber filament. The secret is to proceed cautiously and make little changes to your printer's configuration. PA carbon fiber filament has special qualities that need to be adjusted. You will need to modify the temperature and speed of your extruder because it is more abrasive and rigid than ordinary PLA or ABS. Raise the temperature of your nozzle to 260–280°C to begin. The filament will pass through the extruder more easily because to this increased heat. It can also be necessary for you to reduce your print speed to 30 mm/s or less. The filament will have more time to melt and extrude correctly at the slower speed.

Take extreme caution when loading or replacing the filament. Your skin may become irritated and splintered by the tiny carbon fibers. Put on safety glasses and gloves. Because the fibers are conductive as well, take out any loose strands from the extruder or spool before printing. Instead of using brass nozzles, use ones made of hardened steel. A typical brass nozzle will be swiftly worn down by the carbon fibers. A steel nozzle will withstand multiple prints because it is stronger and more resilient.

Use of a nozzle of at least 0.5 mm is suggested. The bigger size reduces blockages by giving the carbon fibers more space to travel through. Additionally, a larger nozzle will result in a stronger, longer-lasting final print.

You'll quickly start printing robust, lightweight parts with a few tweaks to your standard configuration. It's important to move gently, have patience when some prints don't work, and make little adjustments. You'll be rewarded with gorgeous prints that highlight the beauty of carbon fiber once you've adjusted the ideal temperatures and speeds for your printer and filament.

Conclusion

These are just a few of the best applications for PA carbon fiber filament that will enable you to achieve even greater success with your 3D printing projects. This flexible filament is ideal for printing robust engineering prototypes, lightweight remote control vehicles, or incredibly stylish flowers and figurines. When dealing with PA carbon fiber, the options are unlimited because of its strength, resistance to temperature changes, and flawless surface finish. I hope these suggestions gave you some ideas for your own projects. Just make sure that before you begin, you adjust the settings and pair it with the appropriate nozzle. Now go use PA carbon fiber filament to unleash your creative potential!

Leave a Reply