You've made the decision to learn more about 3D printing and are wondering what kind of filament to use initially. You only need to consider ABS filament. This popular thermoplastic is ideal for any desktop 3D printer as an all-purpose material. Acrylonitrile butadiene styrene, or ABS, is an oil-based plastic that prints cleanly and yields strong pieces.

You can make anything with this flexible filament, from toys and décor to functional components and prototypes. The temperature at which ABS prints is higher—between 210 and 230 °C but the outcome is parts with good interlayer adhesion and durability against breaking. Because of the material's small give, printed items won't break if they are dropped. It also resists chemicals well and won't deteriorate with time.

The possibilities with ABS filament are endless for the do-it-yourself manufacturer or enthusiast. From the comfort of your own home, you can make any parts or components you require in any color. Say goodbye to rushing to the hardware store every time you need a specific tool or trinket. Your 3D printer, a spool of ABS filament, plus your creativity will allow you to quickly produce interesting and useful creations.

What Is ABS Filament?

One of the most popular materials for 3D printing is ABS filament. Acrylonitrile butadiene styrene, or ABS, is a thermoplastic polymer that is resilient to impact, robust, and long-lasting.

The best use case for ABS filament is in functional prototypes and parts. It can resist higher temperatures because of its high melting point, which is approximately 105 °C. Moreover, it resists chemicals and is difficult to dissolve in the majority of standard solvents. Because of this, ABS is perfect for outdoor applications, automotive parts, and mechanical parts.

Key characteristics of ABS filaments include:

- Impact resistant: ABS is able to withstand some abrasion without cracking.

- Sturdy: ABS components withstand stress and strain well and endure a long time.

- Heat resistant: Common chemicals and solvents do not readily harm or dissolve ABS.

- Adaptable: ABS may be painted, machined, and sanded to produce a variety of finishes.

- Cost-effective: ABS is among the most economical materials for 3D printing.

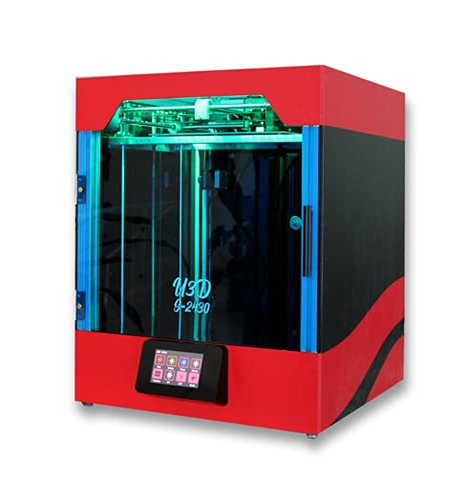

To print ABS filament, a 3D printer with a heated build plate is needed. To get good adhesion, you need to preheat the build plate to between 100 and 110 °C because ABS has a higher melting point. Additionally, since melting ABS may create scents, you'll need enough air.

ABS filament can create durable, high-quality 3D prints for a variety of uses when the settings are just perfect. ABS is a reliable material for all-around 3D printing.

Key Properties and Benefits of ABS for 3d Printing

One of the most adaptable materials for 3D printing is ABS filament. The following are some of the main characteristics and advantages that make ABS a great option:

Durability

ABS is a very strong material that is not easily broken by strong blows. ABS parts are robust and durable; they can withstand knocks and impacts that would break or fracture other types of plastic. Because of this, ABS is perfect for functioning items like phone casings, mechanical parts, and automotive components.

Heat Resistance

Because ABS has a high melting point, it can be exposed to temperatures of up to 105 °C without losing its shape or deforming. ABS parts can be used in higher-temperature settings where other polymers would melt because of their heat resilience. But, a 3D printer that can achieve these temperatures is necessary for printing ABS due to the hot end and bed temperatures needed.

Flexibility

ABS possesses some flexibility in addition to its extreme durability. Because of this, ABS components have a great resilience to impact and don't break easily. Because of ABS's flexibility, intricate parts with thin walls and minute features can be printed without cracking.

Post- Processing

ABS components can be painted, machined, and sanded to provide a polished, seamless surface. ABS is a material that readily takes paint and other coatings and can be dyed to create pieces in a wide range of unique colors. With ABS printed parts, an amazing array of personalization and finishing effects are possible thanks to these post-processing choices.

The combination of ABS's exceptional strength, resilience to heat, pliability, and customizability makes it an excellent choice for 3D printing materials. You'll find that ABS is a very versatile plastic with many uses once you start printing with it.

Best Uses for ABS Filament

Prototyping

ABS is frequently used to create product and part prototypes. Because of its strength, you can test physical designs and observe how they perform in actual environments. To get a polished surface, ABS prototypes can be machined, painted, and sanded. Before completing a design, many product designers use ABS to make several prototype revisions.

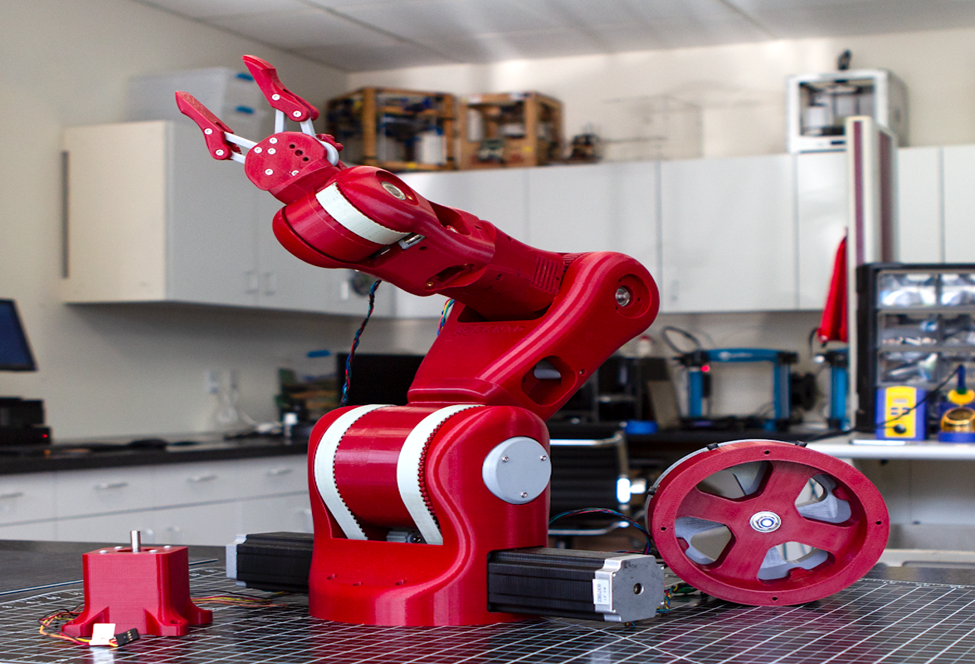

Mechanical parts

Do you need a special part to construct something new or fix some equipment? ABS is a fantastic option. ABS can be printed to create parts like handles, clips, gears, bushings, and bushings.

Parts that can withstand physical loads are produced by its toughness and layer adhesion. Additionally, ABS parts are resistant to chemicals well enough that they won't deteriorate in the presence of oils, greases, or solvents.

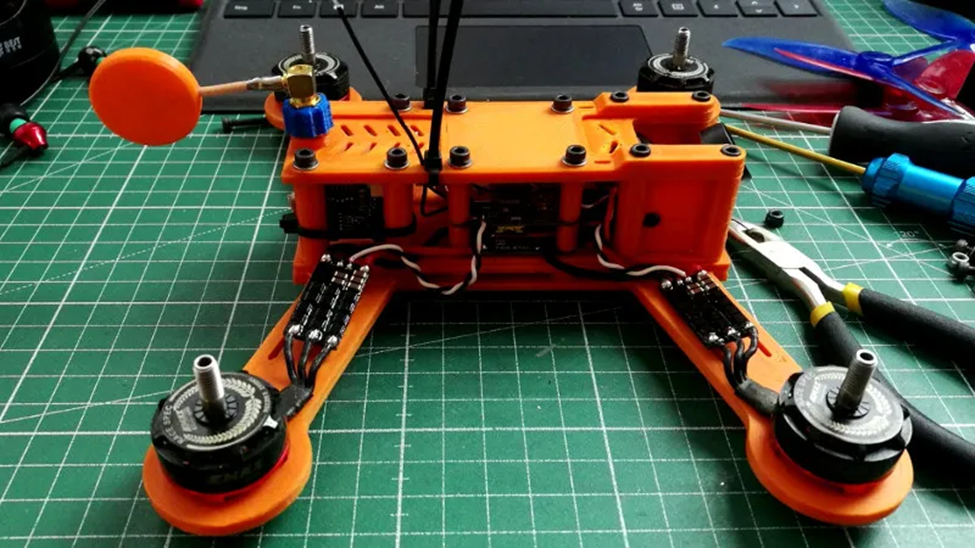

Drones and RC vehicles

ABS is suited for printing parts for RC cars, drones, and other remote-controlled gadgets because of its resilience to impact. ABS can be printed on parts like bumpers, propellers, and chassis parts to withstand crashes and collisions. Its suppleness makes it ideal for printing pieces that might be subjected to stress.

High-heat applications

ABS can tolerate temperatures up to 105 °C without deforming because of its high glass transition temperature. This makes it a viable option for situations where heat accumulation is an issue or for printing items that are utilized close to heat sources. ABS is a good material to print with for items like fan ducting, electronic enclosures, and tiny appliances because of its heat resistance.

In conclusion, ABS filament is a great option if you require a strong 3D printing material for applications requiring heat, prototyping, or creating long-lasting parts. Numerous practical and imaginative applications are made possible by its strength, hardness, and exceptional heat resistance.

Print Settings and Tips for Printing with ABS

For excellent results, there are a few settings and considerations to make while printing with ABS filament.

Build Plate Adhesion

You can use a coating of painter's tape to increase adhesion. Apply ABS slurry or Kapton tape to the build plate. Acetone and ABS filament are combined to make ABS slurry, a sticky covering. By keeping the area surrounding your ABS print at a steady temperature, an enclosure for your printer or a draft shield can be helpful.

Cooling and Layer Times

Reduce the print speed so that each layer has ample time to solidify and cool before the next one is put on. Overprinting can lead to layer lifting and warping. To expedite the cooling process between layers, use a fan. To maximize bed adhesion, turn off any cooling fans for the first few layers. Then, turn on the fans to enhance bridging and overhangs. Layer times that are slower, ranging from 20 to 30 seconds, also allow the filament to stick to the preceding layer longer.

Ventilation

When heated, ABS emits vapors that some people may find uncomfortable or disagreeable. Operate your printer away from inhabited areas in a well-ventilated environment. As was already said, an enclosure can aid in fume containment. In some settings, activated charcoal can aid in odor reduction.

You can quickly produce sturdy, excellent ABS prints by fine-tuning your printer's parameters, employing the best bed adhesion technique for your setup, and maintaining the right atmosphere for ABS.

Conclusion

That's it—ABS filament is a versatile material for 3D printing. Makers and enthusiasts have many options with this material, ranging from crafting robust mechanical components to constructing personalized phone cases. The best thing is how simple and inexpensive ABS filament has gotten. ABS plastic may now be used to create practical and interesting objects without the need for an expensive commercial 3D printer. A few spools of ABS filament and an inexpensive desktop 3D printer will let you create whatever you can think of. There are no limits! Thus, why do you delay? Get creative, load up your 3D printer, and explore the possibilities with ABS filament.

Leave a Reply