Have you ever wanted to print a personalized phone cover or a brand-new pair of shoes right away from the comfort of your own home? This futuristic idea is rapidly becoming a reality thanks to advancements in 3D printing technology. The fashion sector is not an exception to how 3D printers are transforming the way we design and manufacture items. These cutting-edge printers enable everyone from big fashion labels to independent designers to swiftly prototype new ideas and even print finished goods on demand.

They do this by converting digital designs into tangible things. With 3D printing, designers and consumers alike will have access to customization and on-demand production capabilities, revolutionizing the way we produce and consume clothing. From printing unique outfits to producing one-of-a-kind accessories, the possibilities appear limitless. Prepare for the 3D printed clothes of the future.

Rapid Prototyping Allows Faster Design Iterations

Fashion designers can quickly iterate through several designs via rapid prototyping before deciding on a final one. 3D printers are perfect for quick prototyping because they can create designs on demand without requiring expensive molds or equipment.

Faster Design Iterations

Designers can produce a prototype using a 3D printer, make minor adjustments, and then print an updated version right away. Faster design iterations and an overall more efficient process are made possible by this. In less time, designers can experiment with a greater variety of looks, cuts, fits, and patterns. To get the ideal design, they can collect input, make changes, and reprint as needed.

Cost-Effective

Prototyping using 3D printing is significantly less expensive than with conventional techniques. It does away with the requirement for pricey dyes, molds, and tools. Using a 3D printer, designers may easily create several copies of a prototype at a far lower cost. Because of this, designers can now be more daring and imaginative without having to worry about incurring huge expenses.

Customization

3D printing also makes it easy to create highly customized designs. Designers can create unique components made specifically for each buyer. They can play around with various adornments, specifics, and unique touches that might be challenging to accomplish with conventional production techniques. More creative flexibility and control over their ideas is provided by 3D printing for designers.

Fashion design is being revolutionized by 3D printers, which are opening up new avenues for designers to produce cutting-edge apparel and accessories. Fashion design and production are set to undergo a significant transformation because to 3D printing's capacity for rapid prototyping, reduced costs, and customizable possibilities. The 3D printed fashion of the future is here.

Customized and Personalized Fashion Made Accessible

Thanks to 3D printers, clothes can now be customized and individualized. With advancements in technology, 3D printing is starting to alter the fashion business.

Bespoke Fit

You can get clothing made with a 3D printer that precisely fits your specifications. No more costly modifications or searching for the perfect size. A 3D printer can create a blueprint tailored to your body form if you just enter your dimensions. There are countless options for designing one-of-a-kind, custom attire.

Creative Expression

Additionally, 3D printing allows designers greater artistic freedom. They have the freedom to try out novel forms and shapes that would be challenging to produce with conventional production techniques. You can have curved edges, ornate decorations, and unusual silhouettes. This makes it possible to create incredibly avant-garde clothing that resembles wearable art.

Sustainable and Ethical

Eco-friendly changes in fashion are being brought about by 3D printing. It minimizes waste by only printing what is required. There's no unsold stock or extra fabric. Additionally, localized manufacture is made possible by 3D printing, eliminating the need for long-distance clothing shipping. Thus, the carbon footprint is reduced. As the 3D printers can handle much of the work, they also present potential for fair Labor practices.

While it won't completely replace conventional fashion design and production, 3D printing will advance the sector. 3D printed clothes will become more widely available, reasonably priced, and mainstream in the upcoming years. Both ready-to-wear and couture companies will employ 3D printing to give their customers even more personalization and customization options. 3D printing is the way of the future in fashion. And with 3D printers, that future is here now.

Sustainable Manufacturing with Reduced Textile Waste

By decreasing textile waste, 3D printing technology is helping manufacturers and designers produce clothes in a more sustainable manner. Using only the necessary quantity of material, 3D printers construct clothing layer by layer as opposed to cutting out patterns from big bolts of fabric. This enables highly tailored goods with minimal surplus.

Zero waste pattern cutting

Familiar pattern cutting techniques can waste up to 15% of the fabric. This is avoided by 3D printers, which use body scan data to create clothing directly onto models. They create three-dimensional objects by fusing together thin layers of materials, such as nylon powder or polyurethane thermoplastics. There is essentially no material waste in this "additive" method.

On-demand productions

Additionally, on-demand manufacturing is made possible by 3D printing, which eliminates the need to estimate how many items of each size and style to make in advance. As a result, there is less overstock and clothing that ends up in landfills. Without having to deal with a warehouse full of unsold inventory, designers can quickly modify the 3D template to produce a new version of a style if it isn't selling well.

Custom sizing

Precise measurements obtained from 3D body scanners enable the creation of personalized apparel for each consumer. This "made to measure" method lowers returns and guarantees a flawless fit. Personalized elements like a customer's name or initials can even be incorporated into the design thanks to 3D printing. For all of these reasons, 3D printing reduces textile waste and environmental impact while providing a more environmentally friendly option for the fashion industry.

Innovative Materials and Textures Possible With 3D Printing

Fashion designers now have access to an endless array of materials and textures thanks to 3D printers. Designers are no longer constrained to materials and fabrics that can only be stitched or sewed together; instead, they may now create anything they can dream of.

Flexible and form-fitting materials

Materials that precisely fit your body can be printed by 3D printers. These rubbers and plastics, sometimes referred to as elastic or flexible materials, bend and move with your body. Consider swimsuits, body suits, or sportswear that fits snugly against the skin. These materials are perfect for activity or workout apparel because they are water resistant and sturdy.

Embossed and textured surfaces

Using traditional production techniques, it would be practically difficult to generate the rich textures, embossing, and surface details that are feasible with 3D printing.

Surfaces might have a woven appearance or be uneven, wavy, and dimpled. These embellishments may be applied all over the garment or just at specific areas to draw attention to them. In addition to adding visual interest, textures can simulate richness or weight without really weighing anything.

Metallic and glow-in-the-dark materials

Certain 3D printers can print with metallic filaments, producing lustrous, shiny apparel and accessories. Silver, gold, and rose gold are common choices. Moreover, materials that glow or light in the dark can be printed; these are perfect for theatrical, cosplay, or club clothing. These cutting-edge materials create new opportunities for self-expression and push the limits of what is feasible in the fashion industry.

Although the industry of 3D printing for fashion is still in its infancy, creative designers have only just begun to explore its potential. The development of new printing methods and materials means that 3D printed apparel has a promising future. What are you going to design? There are countless options!

3D printers are paving the way for the fashion of the future. The way manufacturers and designers make apparel and accessories is changing as a result of these advanced machines.

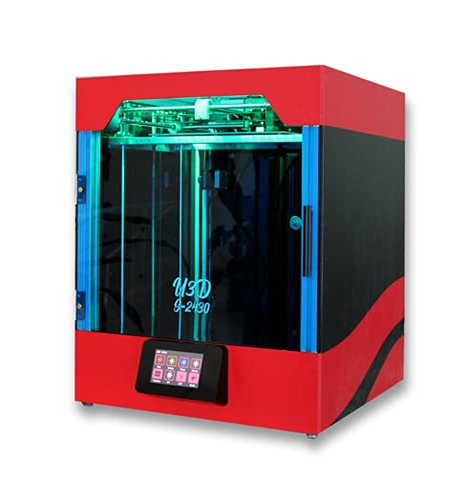

3D printers use computer control to print successive layers of material to create three-dimensional things. Instead of the weeks it may take to create physical prototypes using conventional methods, they enable designers to do it in a matter of hours using digital designs. This implies that before committing to mass production, designers can swiftly iterate and make style adjustments.

As a customer, 3D printed clothing might imply precisely fitted, personalized clothes that are created according to your precise dimensions and personal preferences. A few businesses have already begun testing 3D printed jewelry, purses, shoes, and clothes. They can incorporate flexible materials and sophisticated shapes not attainable with standard manufacturing. One day, you could be able to order personalized clothing directly from the comfort of your home and have it delivered in three dimensions.

The manufacture of ethical and sustainable apparel is also made possible by 3D printing. Because only what is required is printed, waste is decreased. Additionally, parts can be recycled and reprinted into fresh patterns. Furthermore, 3D printing reintroduces production to nearby areas and lessens dependency on foreign firms employing dubious labor practices.

Though it is still in its infancy, 3D printed clothes will probably change the way we create, manufacture, and purchase apparel. It makes personalized and custom-fit fashion available when and when you want it, thanks to an on-demand production strategy. For the technology to really upend the mass-market fashion sector, speed, scale, and material capabilities still need to be improved. But 3D printing has the power to transform our understanding of style and self-expression and open up high fashion to everyone. 3D printing is the way of the future for fashion, and it's only getting started.

Conclusion

That gives you an idea of how 3D printers are changing the fashion industry. The options appear to be infinite. You might be wearing personalized 3D printed shoes, accessories, and perhaps full outfits in a few years that are tailored to your exact specifications in terms of both body type and style. Customization and personalization are the way of the future, and retailers and designers are realizing this. It will soon be possible to obtain 3D body scans to guarantee the ideal fit and have your measurements saved for simple reordering. Creativity and experimentation are made possible by 3D printing without the typical high prices and risks. It creates chances for ecologically responsible production and independent designers. Technology is only going to get cheaper, faster, and better. Before you know it, 3D printers might be producing the newest fashion trends and opening up high fashion to everyone. 3D printing is the way of the future, and it's coming to a closet near you.

Leave a Reply